Testing of Electric Motors for Diagnostics & Predictive Analytics

Company: Enertics Inc.

Funder: Ontario Centre of Innovation

The Energy & Power Innovation Centre (EPIC) provides expertise and facilities to support Canadian companies with their operational challenges with a particular focus on energy and resource management. EPIC also supports utilities and electrical companies with developing new solutions, as well as training in state-of-the-art facilities.

EPIC is also home to the Energy & Power Technology Access Centre (TAC), a national resource for

the Canadian manufacturing and agri-food sector. As a TAC, EPIC helps companies who would like to adopt energy technologies that can reduce operating costs throughout the manufacturing process and/or de-risk the implementation of new technologies.

Project Summary

EPIC Project Team: Patrick McInnis, Quang Nguyen (student), Mariano Arriaga

Enertics Inc Project Team: Bobby Sagoo, Varinder Sembhi

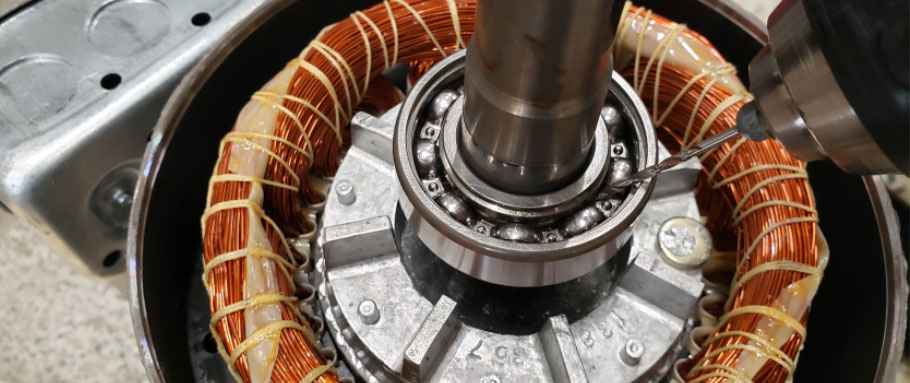

Enertics Inc. has partnered with Mohawk College's Energy & Power Innovation Centre to complete third-party testing of their motor health monitoring system (LVMM 100), using both test-bed and industrial conditions. The lab's test-bed allowed the research team to replicate common electrical and mechanical motor fault conditions in a safe and controlled setting while measuring the IoT sensor response from the LVMM 100. These tests allowed EPIC to verify the Enertics system analytics for the different fault conditions from the simulated cases.

The industrial setup used Mohawk College facilities to install the LVMM 100 device in two running electric motors to identify sensor data trends over extended operating times, as well as testing the unit’s communication capability in a challenging industrial environment.

Industry Challenge

Electric motors are used in a variety of critical and non-critical industrial applications and can be expensive assets to replace. Unexpected downtime or break-downs can be costly, resulting in lost revenue and, in some cases, catastrophic damage. Although most industrial companies undertake preventive maintenance programs, those programs do not provide appropriate alerts and alarms for any anomalies before they become major faults. An automated system providing online diagnostics and proactive health warnings about their motors brings tremendous value to these companies.

About Enertics

Milton, Ontario-based Enertics provides technology solutions for online monitoring and diagnostics of electrical assets. Enertics has designed a non-intrusive system to monitor the health of electric motors that aims to extend the life cycle of motors by detecting abnormalities before they become faults. The company's product, the LVMM 100 Motor Health Monitor system, uses advanced IoT sensors and Machine Learning-based analytics to continuously monitor motor health; providing proactive alerts and alarms based on advanced diagnostics and predictive analytics.

Lab Test Fault Case Setup

The research team exposed the motors to various mechanical and electrical failure modes, testing the LVMM 100 system detection capabilities using advanced vibration and temperature sensors.

Mechanical Faults

The project replicated common motor mechanical faults such as rotor unbalance, misalignment, loose footing, worn bearing, loose casing, rotor rub, and sudden load variations.

Electrical Faults

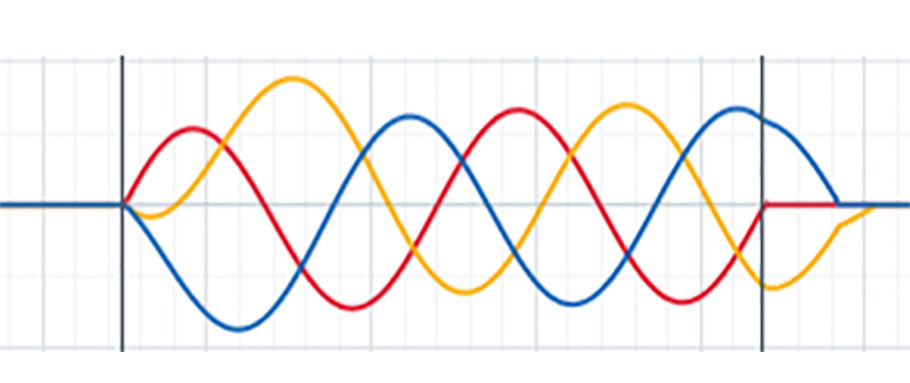

Using the LVMM 100 vibration sensors, the unit was also able to detect electrical faults associated with voltage issues, such as phase unbalance and 1- phase voltage loss.

Spectrum Analysis

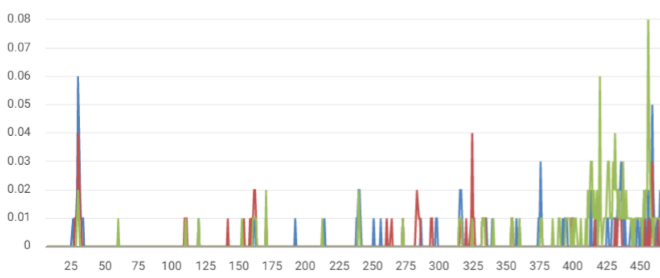

Each simulated fault-mode provided a 3-axis Fast Fourier Transform vibration signature, allowing the Enertics system to validate and correlate to the specific motor faults.

Monitoring

Enertics is targeting industrial facilities that operate a large number of motors in challenging environments. As a case study, the project monitored 24/7 two motors of the same type but with significantly different installation dates and compared their vibration signatures.

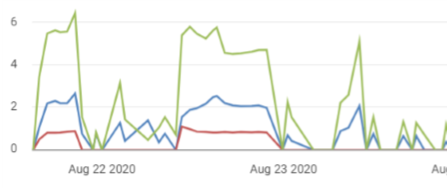

Sensor Data Trending

Enertics analytics platform provides easy access to the motor health historical data and analysis. The ongoing motor monitoring & diagnostics will allow Enertics to identify vibration and temperature patterns that will be able to identify issues at an early stage

Data Transfer

This test not only provided a representative data sample for motor health trending and potential fault analysis; it also helped test and improve Enertics’ data acquisition and communication system in industrial settings.